Skid Steer Mulcher Maintenance: An Overview

Posted by Lee Padgett on 26th May 2022

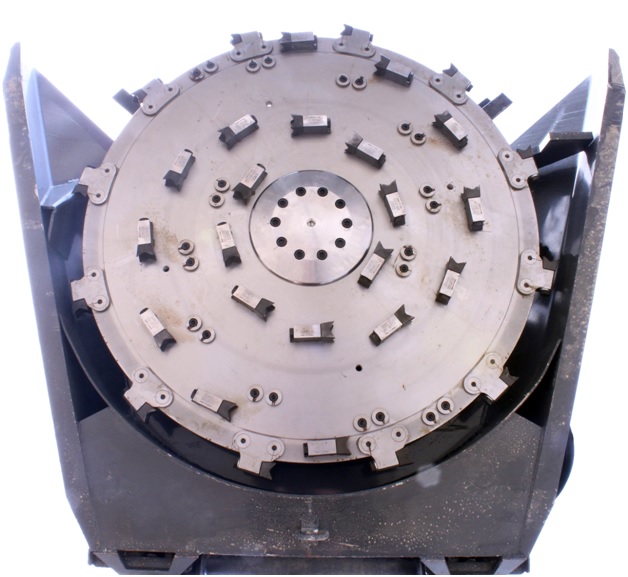

Spartan Skid Steer Mulcher attachments are the toughest in the industry. Ranging from 52” to 82” in overall width, our skid steer mulchers are ideal for tough clearing applications and come with high-torque piston motors and extremely heavy-duty discs, and replaceable four-point quad square teeth.

Our mulchers Never Surrender, make short work of the toughest brush and come with a one-year warranty (hoses, couplers, and teeth are not covered, though teeth are replaceable). However, make sure to observe the following maintenance best practices for your Spartan Equipment skid steer mulcher.

Before Operation or Service

Skid steer mulcher teeth may be very sharp and hydraulic lines operate under immense pressures. Do not attempt to operate or maintain our equipment without protective eyewear, gloves, and footwear.

Note on inspecting hydraulic lines: Always release hydraulic system pressure from the mulcher circuit before inspecting, removing or maintaining the system.

Never attempt to inspect leaks in hydraulic lines using your hand or body parts. A pinhole leak of hydraulic fluid will exit the line under immense pressure that can penetrate skin and cause life threatening injuries. Use a piece of paper or cardboard to detect leaks.

Before Every Use

Before attempting to operate a Spartan Equipment skid steer mulcher, first ensure that all nuts, bolts, pins, and keepers are in the right place and are tightly installed. Replace any worn or missing fasteners before operation.

Ensure that all safety decals are present and visible. Clean or replace any that are dirty, obstructed, or missing.

Inspect the system in order to locate any oil leaks. Repair damaged parts before replacing them.

Using caution, carefully inspect the disc mulcher’s teeth. Wear gloves and protective footwear as teeth can be very sharp. Chipped, worn, or dull teeth can impede the cutting ability of the disc mulcher. Replace these before use if you believe that tooth wear is adversely impacting the mulcher’s ability. (Please refer to the Disc Assembly Manual before attempting to remove or replace the disc and teeth.)

The Importance of Routine Lubrication

Without proper lubrication, the bearing housing of the disc mulcher will fail; proper lubrication is also essential to the effective, efficient operation of this skid steer attachment.

Therefore providing proper lubrication is vital. Before operation, ensure that the oil level in the gearbox is adequately filled.

First, level the attachment and cut power. Remove the motor from the gearbox and inspect the oil level. If it is low, fill it with ISO 150 EP gear oil lubricant until it is filled.

At the end of the season, remove the motor from the gearbox and tilt the attachment to drain out the old (or siphon it out instead). Then, refill the attachment to the proper level and reattach the motor.

Note: the gearbox oil should be changed every 2500 operating hours, regardless of any other factors. Old oil should be drained, measured, and then the appropriate volume should be replaced. Every time you change the oil, you should grease the bearings as well. Fill the bearing cavity with a grease gun until it is full.

Each Week

To perform a quick assessment of the condition of the teeth, each week, raise the attachment off the ground and then tilt it to the 90° position. Lower it to the ground and test the performance - sharp teeth will cut much more efficiently than dull teeth.

When manually inspecting teeth, never position yourself in such a way that any body part is underneath the unsupported cutter deck.

Every Season

After every season, inspect the attachment for any loose or worn parts that will need to be replaced before the following season.

Disassemble the disc assembly and inspect every 1000 operating hours (or less, with heavy use or if you suspect premature wear). Visually inspect the teeth and disc and replace worn parts as needed.

Every season, you should clean and sand any worn or scratched areas. Any areas where the painted finish has worn off are subject to rust. Cleaning and refinishing with an appropriate equipment paint (available at most hardware stores) will help prevent rust damage.

Between uses, and at the end of each season, store your skid steer & mulcher under an enclosed structure such as a shed. If you must leave it outside, cover it with a waterproof tarp to provide a better level of protection against the elements.

A Note on Replacing Parts

When replacing worn or damaged parts, use only genuine parts from Spartan Equipment. Please consult the Skid Steer Mulcher Owner’s Manual - link below - and specify GPM requirements when ordering parts.

For More Information on Skid Steer Mulcher Maintenance

This guide is not complete. For a more thorough guide to skid steer mulcher maintenance, please consult the official Spartan Equipment Skid Steer Forestry Mulching Disc Owner’s Manual, which you can view at the previous link. You can also contact us for further assistance at 1-888-888-1085.