Posted by Spartan Equipment on 21st Oct 2025

Professional landscapers and contractors face a critical decision when selecting equipment for sod installation projects: investing in the right tools can dramatically impact efficiency, quality, and profitability. Among the essential attachments for skid steer operations, sod rollers stand as fundamental equipment for achieving seamless turf installations. Spartan Equipment offers two distinct sod roller models designed to meet different operational needs—understanding the key differences helps professionals make informed purchasing decisions that align with their specific business requirements.

Standard Skid Steer Sod Roller: Simplicity and Reliability

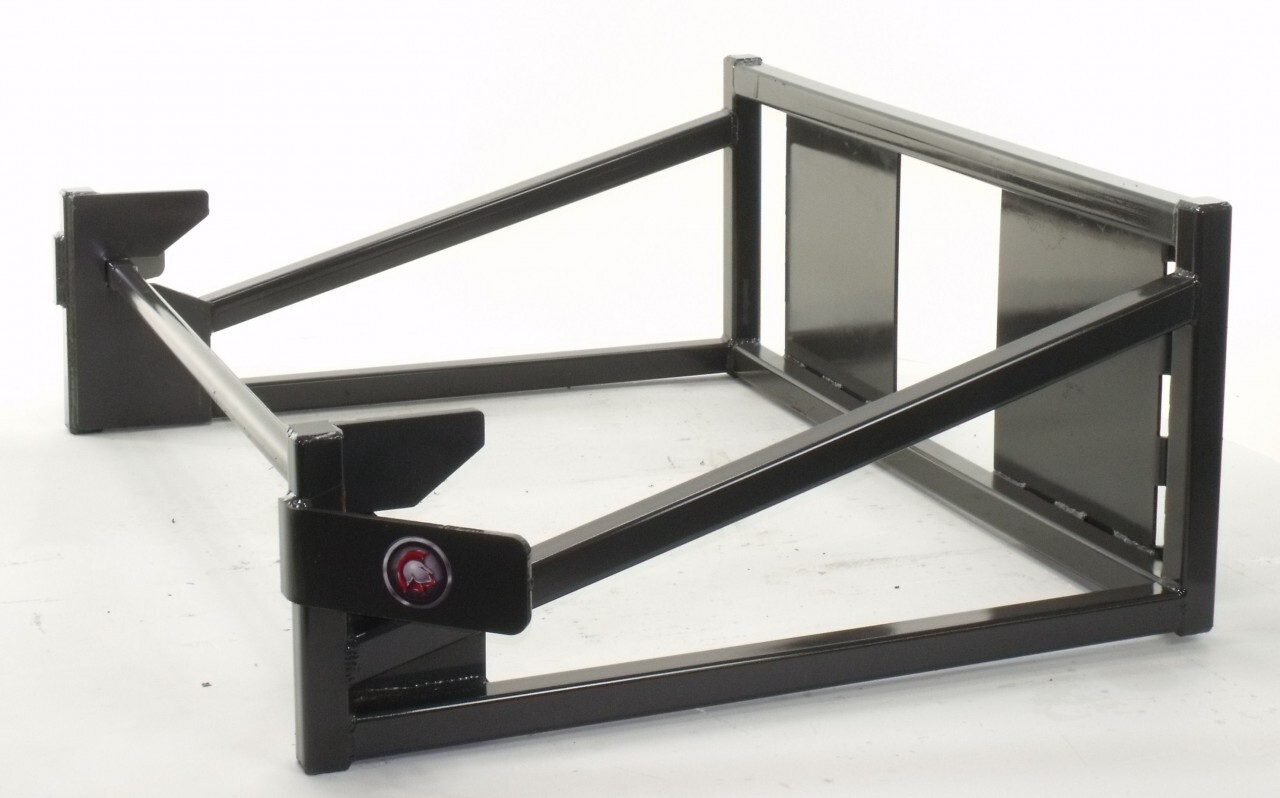

The Standard Skid Steer Sod Roller represents a straightforward, mechanical approach to sod installation. Built with a strong tubular frame, this attachment handles rolls of sod up to 48 inches wide and accommodates rolls up to 60 inches in diameter. The defining characteristic of this model is its simplicity—requiring no hydraulic connections whatsoever.

Key Features:

-

Mechanical Design: No hydraulic system required, reducing complexity and potential maintenance issues

-

Wide Compatibility: Handles sod rolls 24-48 inches wide

-

Large Diameter Capacity: Accommodates rolls up to 60 inches in diameter

-

Tubular Frame Construction: Robust steel construction built for durability

-

Core Requirements: Designed for fiber or plastic cored rolls of sod

-

Universal Quick-Attach: Compatible with standard skid steer universal quick-attach systems

This model excels in applications where simplicity, lower initial cost, and mechanical reliability take priority. The absence of hydraulic components means fewer potential failure points and reduced maintenance requirements.

Hydraulic Sod Roller with Brake: Precision Control for Demanding Applications

The Hydraulic Sod Roller with Brake introduces advanced control features that significantly enhance operational precision. This premium model incorporates an automatic braking system and relief valve technology, providing operators with enhanced control during critical placement operations.

Key Features:

-

Automatic Brake System: Provides controlled handling as sod unrolls into position

-

Relief Valve Protection: Prevents over-squeezing and damage to delicate sod rolls

-

Hydraulic Control: Operator-controlled release mechanism for precise placement

-

Compatible Width Range: Handles sod rolls 24-48 inches wide

-

Professional-Grade Construction: Engineered for high-volume commercial operations

-

Wear Item Coverage: Note that hoses, couplers, and wear items are not covered under warranty

The hydraulic brake system distinguishes this model from its mechanical counterpart by offering precise control over sod deployment speed. The relief valve serves as a critical safety feature, protecting expensive sod inventory from compression damage that can occur during handling.

When Professionals Choose the Hydraulic Model

Despite the higher initial investment, many professional landscaping operations opt for the hydraulic model in specific circumstances. Understanding these scenarios helps justify the additional expense:

High-Volume Commercial Operations

Large-scale projects involving thousands of square feet of sod installation benefit significantly from the precision and efficiency of hydraulic controls. When installing 50,000+ square feet daily, the enhanced control reduces material waste and installation time.

Premium Sod Varieties

High-end residential and commercial projects using expensive specialty grasses justify the hydraulic model's protection features. The relief valve prevents costly damage to premium sod rolls that can occur with uncontrolled mechanical release.

Slope and Complex Terrain Installation

Projects involving hillsides, berms, or challenging terrain require precise control to prevent sod from unrolling too quickly or bunching during placement. The automatic brake system provides essential control in these demanding conditions.

Tight Installation Windows

Summer sod installation, where timing is critical and sod deteriorates rapidly in heat, benefits from the controlled placement that minimizes handling time and stress to the turf. Temperature-sensitive projects where sod must be installed within 24-48 hours demand efficiency that hydraulic controls provide.

Labor Cost Considerations

Operations facing high labor costs or limited experienced crew availability find that hydraulic controls reduce the skill level required for quality installation. Less experienced operators can achieve professional results with automated braking assistance.

Client Expectations and Warranty Requirements

Commercial and municipal contracts often include strict quality standards and warranty provisions. The consistent, controlled placement achieved with hydraulic systems helps meet these rigorous specifications.

Safety Guidelines for Standard Sod Roller Operation

Proper safety protocols protect operators, crew members, and equipment during sod roller operations. Standard mechanical sod rollers require specific safety considerations:

Pre-Operation Safety Checks

Before beginning any sod rolling operation, conduct thorough equipment inspections. Verify that the attachment is securely locked to the skid steer's quick-attach coupler by performing both visual and functional checks. Confirm that both locking pins are fully engaged and perform a tilt test to ensure the attachment doesn't shift or rattle. Check safety chains to ensure they're properly connected, as these serve as critical backup retention if the primary attachment connection fails.

Operator Personal Protective Equipment

All operators and crew members working near sod roller equipment must wear appropriate personal protective equipment. This includes steel-toed safety boots to protect against crushing injuries, high-visibility vests for jobsite visibility, work gloves for hand protection, and safety glasses to protect against debris. Hard hats should be worn in areas where overhead hazards exist.

Safe Operating Practices

Maintain awareness of all personnel locations during sod roller operations. Never allow workers within the swing radius or operational area of the skid steer while the roller is engaged. Establish and enforce a safe perimeter around the work area, keeping bystanders, children, and pets at least 50 feet away from active operations. When loading or adjusting sod rolls, ensure the skid steer engine is off and the attachment is fully lowered to the ground before approaching.

Terrain and Stability Considerations

Assess ground conditions before beginning operations. Avoid operating on slopes that exceed the skid steer manufacturer's specified limits. On uneven terrain, reduce operating speed and exercise extra caution when changing direction. Be particularly aware of edges, drop-offs, trenches, and unstable ground that could cause tipping or rollover.

Sod Handling and Loading

Exercise caution when loading heavy sod rolls onto the attachment. Sod rolls can weigh several hundred pounds and pose crushing hazards if not properly secured. Never position any part of your body beneath a suspended sod roll. Use proper lifting techniques or mechanical assistance when handling rolls to prevent back injuries and strain.

Weather and Environmental Factors

Avoid operating during adverse weather conditions including heavy rain, lightning, or extreme heat. Wet or muddy conditions can create slippery surfaces and unstable footing. During summer heat, monitor both operator heat stress and sod temperature, as overheated sod can deteriorate rapidly.

Safety Guidelines for Hydraulic Sod Roller Operation

Hydraulic sod rollers require all the safety protocols applicable to standard models, plus additional considerations specific to hydraulic systems:

Hydraulic System Safety

Conduct thorough inspections of all hydraulic components before each use. Check hydraulic hoses for signs of wear, cracking, abrasion, or damage that could lead to sudden failure. Verify that hydraulic couplers are properly connected and secured to prevent leaks or hose separation during operation. Never operate equipment with damaged or leaking hydraulic lines, as high-pressure hydraulic fluid can cause severe injection injuries.

Pressure Release Procedures

Before disconnecting hydraulic lines or performing any maintenance on hydraulic components, release all system pressure according to manufacturer specifications. Hydraulic systems can maintain dangerous pressure levels even after the skid steer is shut down. Follow proper lockout/tagout procedures when servicing hydraulic attachments.

Hydraulic Fluid Safety

Understand that hydraulic fluid under pressure can penetrate skin, causing serious medical emergencies requiring immediate treatment. Never use your hands to check for hydraulic leaks—use cardboard or paper to detect spray. If hydraulic fluid injection occurs, seek immediate medical attention as delayed treatment can result in amputation or permanent disability.

Relief Valve Function and Testing

The relief valve serves as a critical safety feature protecting both the sod and the hydraulic system. Test relief valve function during pre-operation checks by gradually increasing pressure and verifying proper release. Never bypass, disable, or adjust relief valve settings beyond manufacturer specifications, as this can lead to system damage and create safety hazards.

Brake System Operation

Familiarize yourself thoroughly with the automatic brake system's operation before beginning work. Understand how the brake engages and releases, and practice controlled sod deployment in a safe area before starting actual installation. The brake system should provide smooth, controlled release—if sod unrolls too quickly or jerks during deployment, stop operations immediately and inspect the system.

Hydraulic Coupler Connection and Disconnection

Always connect and disconnect hydraulic couplers with the skid steer engine off and all hydraulic pressure relieved. Clean coupler ends before connecting to prevent contamination from entering the hydraulic system. Ensure positive engagement of quick-disconnect couplers by listening for the audible click and attempting to pull them apart.

Routine Maintenance and Inspections

Implement a regular maintenance schedule that includes inspection of all hydraulic components. Check hydraulic fluid levels according to manufacturer recommendations and inspect for contamination. Include hydraulic system components in annual or periodic equipment inspections. Document all inspections and maintenance activities to maintain warranty compliance and ensure accountability.

Universal Safety Protocols for All Sod Roller Operations

Regardless of which model you choose, certain safety principles apply universally to sod roller operations:

Training and Competency Requirements

Ensure all operators receive comprehensive training on both the skid steer host machine and the specific sod roller attachment before beginning independent operations. Training should cover equipment operation, safety procedures, emergency response protocols, and proper sod handling techniques. Operators should demonstrate competency through supervised practice before working independently.

Site Preparation and Hazard Assessment

Conduct thorough jobsite assessments before beginning sod installation. Identify and mark underground utilities, irrigation lines, and other subsurface hazards. Clear the work area of debris, rocks, and obstacles that could interfere with operations or create tripping hazards. Establish clear access routes and staging areas for sod delivery and equipment movement.

Communication and Coordination

Establish clear communication protocols between the skid steer operator and ground crew members. Use hand signals or two-way radios in noisy environments where verbal communication is difficult. Implement a "no-go zone" policy that prohibits workers from approaching the equipment until the operator signals it's safe.

Emergency Preparedness

Develop and communicate emergency response procedures for common scenarios including equipment malfunctions, injuries, and hydraulic system failures. Ensure first aid supplies are readily available on the jobsite and that crew members know their locations. Have emergency contact information immediately accessible, including local emergency services and equipment manufacturer support lines.

Attachment Engagement and Verification

Follow manufacturer procedures exactly when engaging sod roller attachments to the skid steer quick-attach system. Never assume an attachment is secure based on appearance alone—always perform both visual verification that locking pins are fully engaged and a functional test by gently tilting or lifting the attachment. Make attachment security checks a mandatory part of your safety culture.

Making the Right Investment Decision

Both Spartan Equipment sod roller models deliver professional-grade performance built on American manufacturing quality. The Standard Sod Roller provides reliable, maintenance-friendly operation ideal for companies prioritizing simplicity and lower operating costs. The Hydraulic model with automatic brake justifies its premium through enhanced control, reduced material waste, and suitability for demanding applications where precision matters most.

Evaluate your specific operational requirements including typical project scale, sod variety costs, terrain complexity, crew experience levels, and client quality expectations. Many successful landscaping operations maintain both models in their fleet, deploying each where it offers the greatest advantage.

Regardless of which model best suits your needs, strict adherence to safety protocols protects your most valuable assets—your crew members. Comprehensive training, rigorous pre-operation inspections, proper personal protective equipment, and clear communication procedures form the foundation of safe, efficient sod installation operations.

Visit Spartan Equipment to explore both sod roller models and determine which attachment best serves your professional landscaping operation. Built with commercial-grade construction, Spartan Equipment attachments deliver the durability and performance that professionals demand.